Robotic Modules

Robotic Investment

Our automated robotic shell building modules are designed to rapidly repeat series of coating, stuccoing, and hardening. These modules can work either series or in parallel.

Robotic Casting

At the heart of our production line is the corbot (coordinated robotic) furnace and casting module. Robots work in symphony to provide continuous production with less down time.

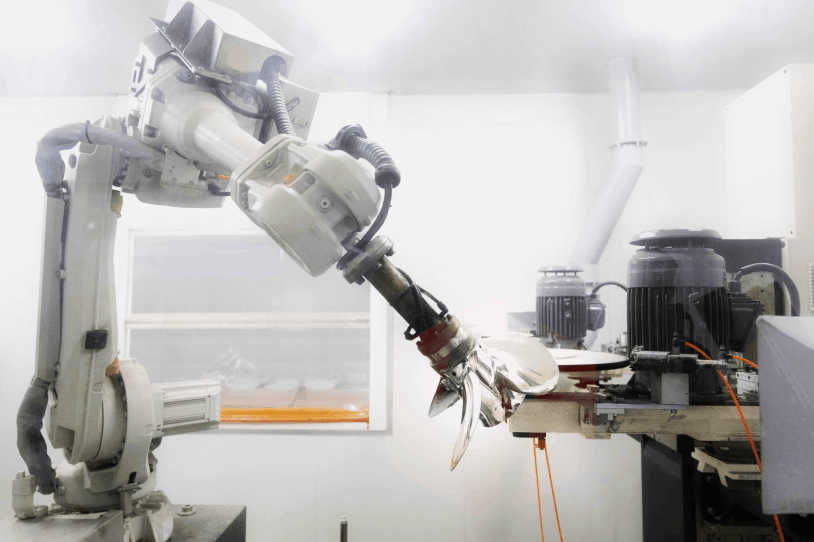

Robotic Finishing

When required, multiple sets of robotic arms work with our experts as a co-intelligence module to perfect the surfaces. These work either in series or in parallel.